Брендом Efarm.Pro був розроблений безпілотний комплекс для розмінування полів. .

Up to 40% of fields are now unsafe for cultivation and contaminated with explosive devices.

The demining complex includes: a drone, a demining robot, an autopilot and a tractor-mounted system capable of withstanding an explosion. The initiator and inventor of this complex was the owner of the Efarm.Pro brand

What does the demining complex consist of?

The complex includes a drone, a demining robot, an autopilot and a towed tractor system capable of withstanding an explosion. The system is controlled remotely from a safe distance, which makes it impossible for a person to be at risk. In this way, the lives of people working in the field will be saved.

The author of this project is Oleksandr Prykhodchenko, owner of the company "Gardarika Tres", resident of the Ukrainian Future business incubator. He is the CEO of the startup Efarm.Pro, which develops technological solutions for the agricultural sector - universal agronavigators and controllers. It was Efarm.Pro navigation systems that became the basis for the creation of a complex for demining fields.

From the first days of the war, Oleksandr Prykhodchenok understood the problem and looked for a way out of it:

"My farmer clients talked about a critical problem - the impossibility of working on mined lands. Those who nevertheless risked going into the field were often blown up by mines, lost their equipment, or even their lives. Given the scale of mine pollution — the UN already called Ukraine one of the most mined countries in the world — farmers would have to wait for years for their turn to clear hundreds and thousands of hectares of land.So the need for alternative safe demining became obvious," says Oleksandr.

How does the demining complex work?

The demining complex provides for three levels of survey of territories and disposal of dangerous objects:

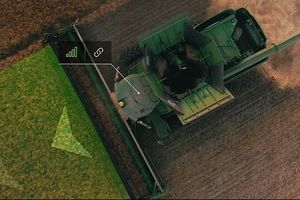

• First, the field is scanned by a drone equipped with appropriate sensors and the function of transmitting the exact coordinates of the location of the explosive devices with georeference. It detects explosives at a depth of up to 1 meter.

• It is neutralized by a demining robot and certified sappers.

• Next, a remote-controlled tractor with a trailed protection system goes to the field, it passes the top layer of the soil, which guarantees safe work.

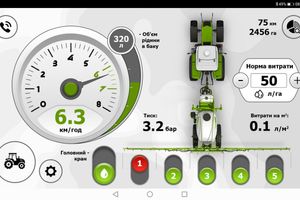

The tractor works in autonomous mode without an operator in the cab. This excludes the possibility of his death or injury. In addition, the equipment is equipped with protective equipment that works according to the principle of a mine trawl. This process guarantees that nothing dangerous will remain in the ground. The system provides for automatic work on large areas with an accuracy of 2 cm along a given route. The tractor passes the field at a speed of 5 km/h, i.e., in a 10-hour working day, it is able to survey 20 hectares of land

Tractor without operator.

Victory of customization of the autonomous autopilot, with the possibility of changing the code and changing the distance.

Control components and supplementary systems

• The controller on the sensor pereshkod;

• Controller for control of swidkistyu, zupinkoy.

• Radio telemetry,

• Remote control. Work according to the task card

• Supervisor of mounted unit before turning

The tractor is equipped with additional armor plates.Zahisna steel, is recognized for use in the construction of transport facilities for the protection of the mines and self-contained vibukhovy outbuildings.

Zahisniy kіvsh or prichipna vykonanі system from mіtsnoї tovstої stalі tovshch. 12 mm. The inner part was lined with armored plates.