CEO of the startup, Oleksandr Prykhodchenko, told ShoTam how the idea of developing a mine-clearing tractor came about, how precisely the unmanned complex can work, and about the social mission of making Ukrainian fields safe.

We became field assistants

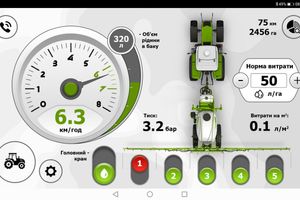

Since 2016, our company "Gardarika Tres" has been engaged in agricultural equipment and specializes in precision farming systems and warehouse storage of grain. We develop and manufacture various navigation equipment, computers for harvesting, and a climate control complex for storage to ensure optimal temperature even in small hangars.

Our first developments were navigation systems for tractors and sprayers, which we call "field assistants." These systems help perform field work more accurately, avoiding gaps and overlaps, which helps farmers increase yields.

Over the past seven years in the market, we have observed that our IoT systems save farmers' initial investments by reducing costs for seeds, fertilizers, water, and pesticides.

We also see that our audience is changing and requires digitization in farm management. If today a grandfather uses a push-button phone, tomorrow he confidently holds a tablet in his hands.

How our technologies reduce CO2 emissions

Over the past years, we have been able to reduce CO2 emissions into the atmosphere by one and a half million tons. This contributes to the development of more sustainable and environmentally friendly agriculture.

Here's how it works:

- Navigation systems provide more accurate movement of agricultural machinery in the field. This reduces fuel consumption and, accordingly, reduces CO2 emissions into the atmosphere;

- Also, navigation systems, due to localized application in the field, reduce the use of chemical fertilizers and pesticides, which can negatively affect the environment and contribute to emissions during their production;

- Navigation systems reduce water consumption, which also contributes to lower CO2 emissions;

- More precise positioning of agricultural machinery and better process management also help improve yields and product quality. Increasing production per unit area reduces the need to seek new plots. This way, we preserve forests and natural ecosystems, which can be CO2 sinks.

The beginning of the war coincided with the sowing season When the full-scale war began, many employees remained in Ukraine, some of them were in occupation, and I was in Kyiv. Despite the difficult times, we believed in better scenarios, so I decided to stay in the capital.

Already the next day after the invasion began, we received a phone call from a farmer who placed an order for a guidance system based on a neighbor's recommendation. The farmer said that the fields he needed to sow were mined. But despite the danger, he had to work in March, as it was time for sowing.

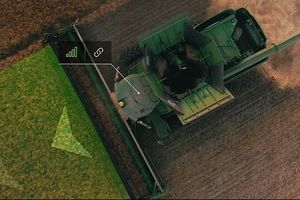

Gradually, with the team, we began to think about how farmers could work in mined fields - it's dangerous. So we decided to develop our mine-clearing tractor to eliminate human resources in this risky work.

We already had considerable experience working with autopilots and navigation systems that successfully operated in Ukrainian fields. This inspired us to create a device that would eliminate the risk for people in mined areas. The main task was to develop a machine capable of withstanding the impact of mine explosions.

Digitizing demining

We see that the experience of agriculture can be useful in demining territories. Simple methods that we used to help farmers increase productivity can be applied to demining using modern digital navigation technology. We propose the following steps:

- Using a drone. Initially, to enter the field, we need to treat it with herbicides to get rid of weeds.

- The drone scans the field, equipped with sensors and a function to transmit precise coordinates of the location of anti-tank mines. It detects explosive devices at depths of up to one meter.

- We digitize the contaminated areas of the field and create an accurate map of the placement of explosive devices.

- Certified sappers go to the site of the strike and clear the area of mines.

- Using robotic arms that can assist sappers in demining.

- Launching a mine-clearing tractor on autopilot. The machine itself should include protective equipment developed on the principle of a device that neutralizes mines. We are already working on a better version of the protection system.

Our universal autopilot system eliminates the presence of a tractor driver behind the wheel. This way, we can work with accuracy up to 2 cm. This is possible thanks to Real-Time Kinematic (RTK) technology, which provides satellite positioning systems with precise information about the location.

Currently, after the work of sappers, sometimes there are untreated areas of the field, which can become insidious traps. Often, tractor drivers who sat behind their machines faced explosions and injuries from mines, sometimes buried half a meter deep. Anti-tank mines were even hidden behind a wooden plank, making them almost invisible. In our case, it is possible to control the machine and be at the edge of the field.

Based on tractors, we can create trailer equipment that will absorb the main impact during an explosion. In the future, these machines can help demine not only fields for sowing but also other territories.

Currently, our project is self-funded, and we are looking for donors who could cover the cost of tractors for farmers. Our social mission is to make the field safe and provide farmers with the opportunity to continue working on Ukrainian land. We are also ready to cooperate with leading manufacturers of agro drones to combine our technologies and knowledge. Together, we can change the approach to demining territories, providing sappers with accurate and reliable information about affected areas.