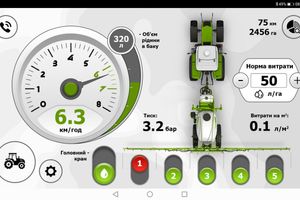

RTK (Real-Time Kinematic) systems represent advanced navigation technology used in various industries, including agriculture. They provide highly accurate positioning and navigation through the use of satellite systems such as GPS or GLONASS in real time.

The operating principle of the RTK system is based on the use of a base station, which continuously monitors signals from satellites and transmits corrective information to mobile receivers on agricultural equipment.

The benefits of using RTK systems for the agricultural sector include:

- High accuracy: RTK systems provide positioning accuracy of up to several centimeters, which allows for more accurate agricultural work in the field, such as sowing, tillage and harvesting.

- Process automation: The use of RTK systems allows you to automate many processes in agriculture due to the ability to connect various agricultural devices to them, such as autopilots and variable fertilizer dosage systems.

- Increased productivity: Thanks to high precision and automation of processes, RTK systems help increase the productivity of agricultural work and reduce the time spent on it.

- Optimize resource use: The precise positioning provided by RTK systems allows for more efficient use of resources such as seeds, fertilizers and pesticides, leading to lower production costs.Improved crop quality: Thanks to more precise control of agronomic processes, RTK systems help improve crop quality and increase yield.

Comparing the economics of working with and without RTK, one can note a significant increase in efficiency and profitability. The use of RTK systems can reduce resource and maintenance costs, increase productivity and quality of work, which leads to increased revenue and reduced costs. Thus, the introduction of RTK technologies in the agricultural sector helps improve its competitiveness and ensures sustainable growth.

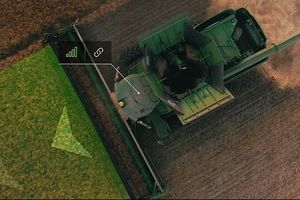

The implementation of RTK systems significantly increases the efficiency and economic performance of enterprises. Let's look at several examples of using an RTK signal for autopilot at different enterprises of different sizes.

Large enterprise:

At a large agricultural holding, the introduction of an RTK system with an autopilot for tillage machines led to a significant increase in productivity. In the first stages, fertilizer use was reduced by 15%, as the autopilot ensured a more uniform distribution of fertilizers on the field. Fuel consumption was also reduced by 10% due to optimization of routes and precision of vehicle movement.

Medium enterprise:

An average agricultural enterprise, having begun to use an RTK signal for autopilot on tractors when sowing, was able to reduce seed consumption by 20%, since the seeder now accurately followed a predetermined route. In addition, thanks to more accurate navigation, it was possible to reduce costs for fuels and lubricants (fuels and lubricants) by 12%.

Small enterprise:

Even on a small family farm, the implementation of an RTK system for autopilot on a combine harvester has led to a significant increase in efficiency. Due to more accurate navigation, it was possible to reduce crop losses by 25%, as well as reduce fuel costs by 15%, since the combine moved along the optimal route without unnecessary repeated passes.

Comparing the figures for resource use with and without an RTK signal, it is clear that the implementation of this technology can significantly reduce costs and increase productivity at all levels of enterprises. Reducing costs for fertilizers, fuel and other material resources leads to a significant increase in economic indicators and an increase in the profits of agricultural enterprises.